Unlocking Growth: The Surprising Advantages of Contract Manufacturing for Your Business

In today's fast-paced and competitive business landscape, companies are constantly seeking ways to optimize operations and drive growth. One strategy that has gained significant traction is contract manufacturing. This approach allows businesses to leverage external expertise and resources, providing a practical solution to the challenges of production and supply chain management. As companies navigate the complexities of scaling their operations, understanding the advantages of contract manufacturing can be the key to unlocking new opportunities and enhancing overall efficiency.

Contract manufacturing offers a range of benefits that can transform the way businesses operate. From cost savings and increased flexibility to access to advanced technologies and specialized skills, partnering with a contract manufacturer can provide the support needed to meet market demands. Whether you are a startup looking to bring your product to market or an established company aiming to improve your production processes, exploring the potential of contract manufacturing could be the game-changer your business needs.

Understanding Contract Manufacturing

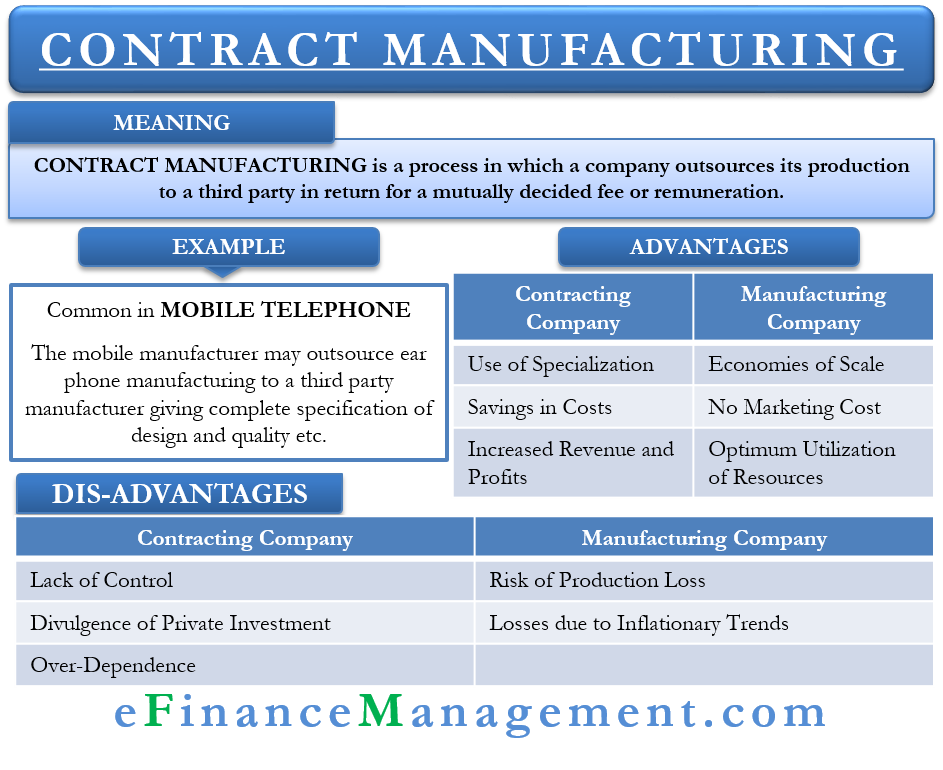

Contract manufacturing is a business arrangement where a company outsources the production of goods to a third-party manufacturer. This practice allows organizations to benefit from specialized expertise and advanced manufacturing technologies without the need for heavy investments in their own production facilities. By partnering with a contract manufacturer, businesses can focus on their core competencies such as design, marketing, and sales while leaving the complexities of production to experienced professionals.

One of the key advantages of contract manufacturing is the flexibility it offers. Companies can scale their production up or down based on demand, which is especially useful in industries with fluctuating market conditions. This ability to adjust production levels without the burden of maintaining excess capacity or workforce ensures that businesses remain agile and responsive to changing market dynamics.

Additionally, contract manufacturing often leads to cost savings. By leveraging the established resources and efficiencies of contract manufacturers, businesses can reduce overhead costs associated with labor, equipment, and facilities. This financial efficiency not only enhances profit margins but also allows companies to allocate more resources towards innovation and improving their product offerings, ultimately driving growth and competitiveness in the marketplace.

Benefits of Contract Manufacturing

One of the primary advantages of contract manufacturing is cost efficiency. Businesses can significantly reduce their production costs by partnering with specialized manufacturers that have established processes and economies of scale. This allows companies to allocate their resources more effectively, investing in other critical areas such as marketing and innovation. With lower overhead costs and access to better pricing on raw materials, firms can improve their profit margins while maintaining competitive pricing.

Another benefit is flexibility and scalability. Contract manufacturing provides companies with the ability to quickly scale production up or down in response to market demands without the need for major investments in equipment or facilities. This adaptability is crucial in today’s fast-paced business environment, where consumer preferences and market trends can change rapidly. By leveraging the expertise of contract manufacturers, businesses can respond to these changes effectively and remain agile.

Additionally, contract manufacturing offers access to specialized expertise and advanced technology. Many contract manufacturers possess advanced machinery, technical knowledge, and industry expertise that may not be available in-house. This access enables businesses to benefit from innovative manufacturing processes and high-quality production standards. By collaborating with these manufacturers, companies can enhance their product quality, reduce time-to-market, and adopt best practices that contribute to overall growth and competitiveness.

Choosing the Right Contract Manufacturer

Selecting the right contract manufacturer is crucial for unlocking the full potential of your business. Start by assessing your specific needs, including production volume, quality standards, and timelines. Research potential manufacturers thoroughly, checking their capabilities and expertise in your industry. Consider factors like technological support, innovation, and flexibility to adapt to changing requirements.

Next, look for a manufacturer with a proven track record of reliability and quality. Reviews from other clients can provide insight into their performance and customer service. Engage in discussions regarding their processes, certifications, and quality control measures. This will help ensure that they not only meet your expectations but also align with your company’s values and goals.

Finally, communication plays a vital role in successful partnerships. Establish a strong line of communication early on and ensure that the manufacturer is responsive and transparent. Regular updates and constructive feedback are essential for a smooth collaboration. By choosing a contract manufacturer who prioritizes relationship-building, you can create a partnership that fuels growth and drives long-term success for your business.